With hull work near completion the stand needs to be created. I will not be using the kit stand.

My choice will be the brass knobs with bolts running thru , and mounted on length of wood.

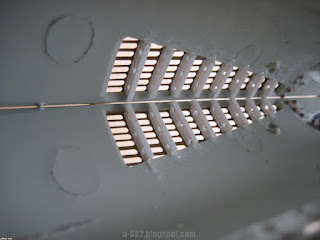

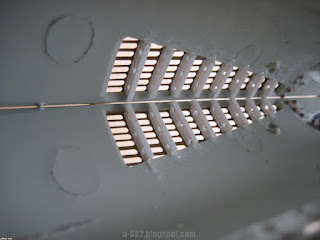

First the holes were drilled.

Looking at the pic abowe right , its aparent it will not offer much torque strength.

The brass washer cut to the size and drilled was glued to the nut , and sides were bent to

prevent sliping.

That fits the cavity of the hull well.

Two 4 cm lengths of steel tube to form the spacer for my "work stand".

The temporary stand to be replaced by proper stand once all the painting has been completed